The Servanté Systems Propcorn Applicator

When a suitable motor supply is found, this popular unit will be back on the market, Ring 01229 583580 for latest news.

The Servante Systems Propcorn applicator is purpose built by popular request, to give a simple, easy and accurate delivery system, applying preservative to grain as it is drawn into the Auger.

It consists of a 12Volt DC flow rate controlled pump, drawing from any size of additive drum, and delivering additive through the purpose built dribble bar designed to avoid blocking. (Spray nozzles are available if preferred.)

Accurate and repeatable flow rates of 0.6 to 3.5ltr/min are achieved by adjustment of the flow control on the pump box, for very moist grain conditions or high volume augers, higher volumes (0.8 to 4ltr/min) can be achieved by changing pump tube, or requesting high flow unit when ordering.

CONTENTS

INSTRUCTIONS

Unpack and check contents. The pump box stands on its base, with controls on top, it can, if required, be mounted onto a surface by opening box and screwing or bolting through the holes in the back.

Connect free end of attached cable to tractor battery, (either a running tractor, or an old battery with a battery charger connected can be used) brown to positive and blue to negative (Cable can be cut to length if required), Pump can be reversed without damage by reversing wires.

From the coil of delivery pipe, cut sufficient length to reach from bottom of drum, through lid to pump position. Slide small jubilee clip over end of pipe, warm pipe in boilling water and push onto lower pump hosetail and fasten with cable tie

Take remaining 10mm delivery tube, warm as before and push pipe onto other pump hosetail and fasten with cable tie, lay out pipe to Auger position and if wished cut to length, push end of dribble bar into flexible pipe and fasten with cable tie.

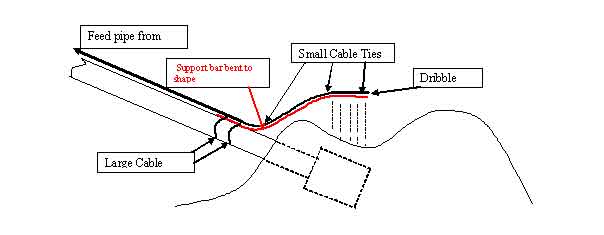

Take a Support bar supplied and using the two large cable ties, fasten to Auger in desired position, with tape or similar between bar and against auger to prevent slipping. (See Diagram below). Bend support bar to shape to position dribble ring over auger intake, and fasten dribble ring to it using supplied cable ties. (Some people seem to prefer just to strap open end of flexible pipe to the auger intake guard.)

WHEN HANDLING

PROPCORN AND ITEMS IN CONTACT WITH IT,

TAKE ALL SAFETY PRECAUTIONS LISTED BY SUPPLIER

Take a lid from a Propcorn drum, and remove the central plug or drill a 12mm hole, feed free end of attached pipe through lid from the top, and slide down to match height of drum, push filter into end of pipe and secure with cable tie (Jubilee clips corrode).

Push filter into drum and allow to sink, feeding in pipe until top can be refitted, this will prevent accidental spillage.

The unit is now ready to run.

APPLICATION

Set speed control to highest (2000 ltr./min.) pull on switch and wait a min for system to fill, when Propcorn runs from dribble ring, turn control to required flow rate, (see application table.) CHECK CONNECTIONS FOR LEAKS AND TIGHTEN IF NECESSARY.

Since 12V DC systems produce a range of ~11 to 14V, for accurate application use a jug to collect a minutes flow and check flow, adjust speed control as required. (This can be done using water earlier in setup if wished.)

Accuracy pays, with Propcorn at £0.85/ltr, being 100ml/min high is £5/hr, or a man’s wage over the day.

Running dry for short periods will not harm pump, but life of replaceable pump tube will be shortened by continued dry running.

When finished, withdraw feed pipe and filter from drum and allow system to run empty, flush through with 20 to 30 litres of water.

DO NOT ALLOW SYSTEM TO STAND FULL OF PROPCORN, FOR MORE THAN A DAY.

APPLICATION RATES

Table gives recommended rate in ml/min.

Example -

Auger moves 8 Tes/Hr and moisture content of grain is 22%. From table above, recommended application rate is 1063 ml/min.

Set flow control slightly above 1000 mark and start pump, when flow from dribble bar is continuous, catch 1 min of flow in a jug and check quantity, adjust control up or down as necessary.

MAINTENANCE

Always flush system after use, and before packing away.

Check pipes and cables for damage and replace as necessary.

Annually replace pump tube. (See pump leaking in trouble shooting).

TROUBLESHOOTING

Pump not running

Check switch on and speed controller is above lowest setting.

Check connections to battery.

Check fuse, (3Amp) replace if necessary. Do not use higher rated fuse.

Check cable for damage and repair as necessary.

Pump running but not pumping

Filter blocked, turn off, remove feed pipe and filter from drum, rinse, remove filter from pipe and wash.

Check feed line is not damaged, replace if necessary.

Pump leaking

Turn off, rinse any spillage away, remove screws from black pump face, remove pump face and rinse face and pump tube, remove damaged tube and replace with new section from supplier, (See picture below) replace face and refit screws. This is also technique for fitting the higher flow rate tubing.

Contact Servanté Systems for more information